We are one of the leading Manufacturers, and exporters manufacturing only the superior quality of

sand by using the quality good raw materials with our qualified engineers, used for processing the

different grades of sand.

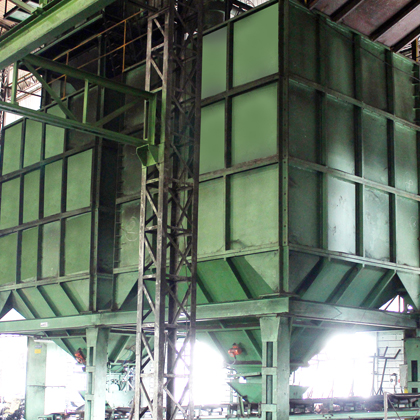

1.Green sand preparation capacity Sand Muller (40 MT / hour).

2. Sand return sytem with efficient equipment like Magnetic separator, Sand screen, Sand cooler and

Bucket elevator, Belt conveyors with magnetic head pulley for removing minute metal chip from return

sand & water sprinkles system to decrease return sand temperature.

3. Larger conveying system to convey the material on time.

4. Modern Dust collector system for dust free plant.

Moulding process is to convert from raw sand plant into shaping liquid, then it take place small

casting in small moulding machines with automatic drop - plate moulding machine.

1.2 Pairs of ARPA 300 simultaneous Jolt & Squeeze machines.

2.FBO-III Mold Size 660X508X130-200/130-120

There are a variety of melting process used in foundry for melt the castings. During melting the iron (in Fahrenheit), which is monitor by Computerised System, in this process we will save our Energy Level to get the good Outcome of the raw materials.

In-house facility for undertaking the Mounting of patterns followed by methoding and rework wherever

required.

We produce exacting precise patterns with ISO 9001 quality standards and tolerances

specified by your engineering drawings. We manufacture new patterns in different ranges in size from

small parts with multiple impressions mounted on cope and drag boards all the way.

Patterns are constructed with high quality materials, such as high - quality hardwoods and epoxy

resins.

Our pattern shops are skilled and experienced with all of our tradesmen.

Core Shop is an important process to make the suitable shapes. The Choice of Core Making is depends on the metal

to be casting, size of the casting, quality of the casting and equipment that, we used for the production and

Energy Source.

1.2nos Cold Box Core Shooter of 5kgs and 10kgs

2.Co2 and air set core making facilities

3.Heating Oven for Core Baking

4.2nos * 250kgs core sand mixer

It involves the removal of core, materials from specific areas and any of unnecessary projections on the

surface

of the castings.

1. We have the Competence for all Fettling Operations like Cutting, Swing Frame Grinding, Finish Grinding and

Shot Blasting.

2. At VeeSaa Foundry, We specialize in providing precision machining solutions for a wide range of industries.

With a focus on quality, reliability, and innovation, we have established ourselves as a trusted partner for

companies seeking superior machining services.

We have a modern In-house testing laboratory for various stages of production.

1.Spectrometer

2.Sieve Shaker with Sieve Test

3.Online Carbon Silicon Analyser

4.Compatibility Tester

5.Brinells Hardness Tester

6.Core Hardness Tester

7.Mould Hardness Tester.

1.

CNC Machining:

Utilizing advanced CNC technology, We deliver precise and complex components with unmatched accuracy.

2.

Prototype Development:

From concept to prototype, Our experienced engineers collaborate with clients to turn ideas into reality.

3.

Custom Fabrication:

Need a unique part? Our skilled craftsmen excel in crafting custom components to exact specifications.

4.

Precision Grinding:

Achieve superior surface finishes and tight tolerances with our precision grinding services.

5.

Assembly and Finishing:

Let us handle the final touches. We offer assembly services and a variety of finishing options to meet your requirements.

Range IN mm

x-800mm, Y-440mm, Z-490mm

Range IN mm

X-500mm, Y-700mm, Z-400mm